Popular Diesel Diagnostic Equipment

Many drivers believe diesel engines to be easier fixes because the components of most trucks are now controlled with computers. You get the impression that because a diesel engine is computerized, the mechanic should be able to hook up a tool and see what is going on almost immediately.

Some specific engine problems are easy to diagnose, yes, but there are still many issues that require a lot of know-how and special equipment. You’ll find this special diesel diagnostic equipment in many mechanic shops, including ours!

Diesel Diagnostic Equipment

Take the diagnosis of something like the fuel injector. Fuel injectors get overworked and weaken over time, just like any other part. Even though they are electronic, the mechanical parts within the injector can also become worn, to the point that they stop working properly. For this, we have to use a scan tool that can pinpoint which components might be causing the trouble, and why. The proper tool will show us a lot of data and the corresponding codes so that we can accurately diagnose and fix the problem.

Take the diagnosis of something like the fuel injector. Fuel injectors get overworked and weaken over time, just like any other part. Even though they are electronic, the mechanical parts within the injector can also become worn, to the point that they stop working properly. For this, we have to use a scan tool that can pinpoint which components might be causing the trouble, and why. The proper tool will show us a lot of data and the corresponding codes so that we can accurately diagnose and fix the problem.

Using the injector example, we’d use a hand-held instrument called a fuel injection analyzer that diagnoses and measures the performance of all types of fuel injection systems, as well as the mechanical injectors used on diesel, gasoline, and liquid natural gas engines. We can then pinpoint which cylinder has the contribution problem and work on that one instead of investigating all of them. It’s often as simple as clipping the analyzer’s ground wire to a chassis ground and applying the sensor to your truck’s fuel injector.

A tool called the G2 Diesel Injector Tester is great for diagnostics and is used onboard while the engine is running. With the G2, you can see which injectors are causing the problem and replace only the worn out or defective ones and identify the right injector spool times. While using it with a laptop isn’t always necessary, it makes logging numbers, codes, and other data easier and can display injector performance on easy-to-read graphs. You can check all the fuel injectors without even having to turn off the engine!

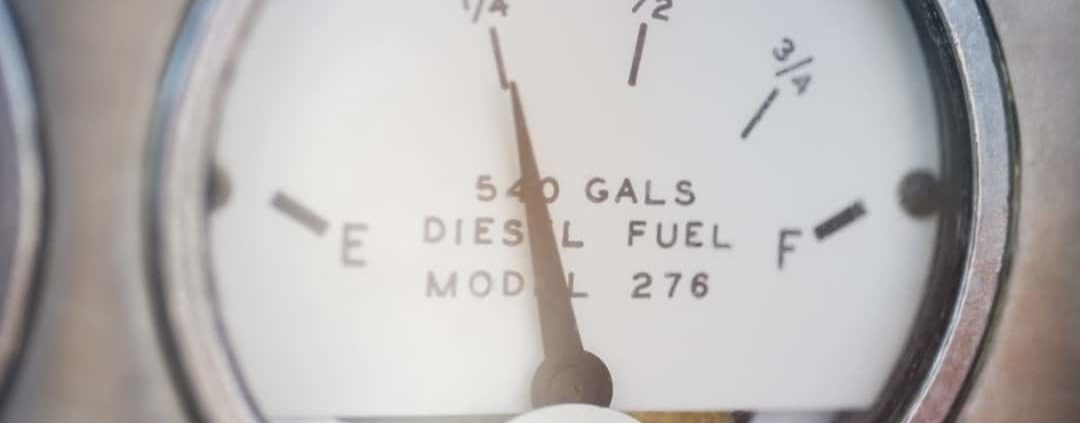

Simple Gauges, Smart Diagnosis

The good thing about electronic diesel equipment is that the technician can link up with a scan tool to analyze data in order to try to pinpoint problems, and the truck doesn’t have to be in the shop. But some problems may be tougher than you might think.

We can use some special tools alongside the diagnostic service equipment that will point us in the right direction. One is the vacuum test gauge, a tool that shows the  difference between outside atmospheric pressure and the amount of vacuum present in the intake manifold. This can tell us a lot about the condition of the engine in very little time! Many parts have their own characteristic effects on the vacuum – valves, the ignition and fuel control systems, piston rings, emission controls, and so on – and you can judge their performance by noting any variations from the normal amount of vacuum created

difference between outside atmospheric pressure and the amount of vacuum present in the intake manifold. This can tell us a lot about the condition of the engine in very little time! Many parts have their own characteristic effects on the vacuum – valves, the ignition and fuel control systems, piston rings, emission controls, and so on – and you can judge their performance by noting any variations from the normal amount of vacuum created

It’s fairly simple: we connect the vacuum gauge as close to the intake manifold as possible, then start the engine. We run it long enough so that the engine can reach its normal operating temperature, and then we note the action and location of the needle on the gauge. How the needle jumps on the gauge (or doesn’t) tells us different engine problems, and we can make an accurate diagnosis with it!